Discover the Unique Features

Why Choose X-Treme Series?

• Internal Humidity Range: 0.5% RH to 95% RH

• Outstanding Performance: Recovers from 50% RH to ≤1% RH

• Internal Temperature Settings: 2°C | 15°C | 45°C | 60°C | | 125°C

• Sensor Accuracy: ±0.3% RH / ±0.5°C

• Security: RFID-based authorized user access

• Real-time Monitoring: Live humidity & temperature data

Advanced Features for Industry 4.0 Integration

• 7” Touchscreen with 800×480px resolution

• Integrated high-precision humidity & temperature sensors

• Built-in datalogger for historical tracking supports Wi-Fi, Ethernet, and USB

• Remote Monitoring System (RMS) compatible with Wi-Fi and Ethernet

• Fully accessible via computers, tablets, or smartphones

Watch our short video and explore all the advanced features in just 2 minutes →

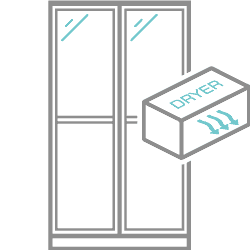

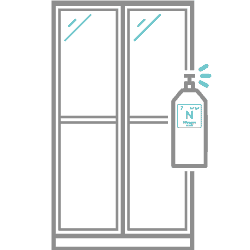

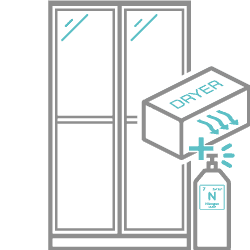

Advantages of Our Auto Dry Cabinet

Precision Dry Storage for Electronics, Aerospace, Defense and More

Some of Our Clients

and many more…

News & Events

In this insightful conversation, Mr. Küçük discusses emerging trends in…

Elektronikmässan 2025

We’ve just wrapped up an exciting two days at Elektronikmässan…

IPC APEX 2025

As EMT Electronics showcased our latest innovation, X-Smart Light –…

X-Treme Connect International 2024

As X-TREME SERIES AUTO DRY CABINETS team we were thrilled…