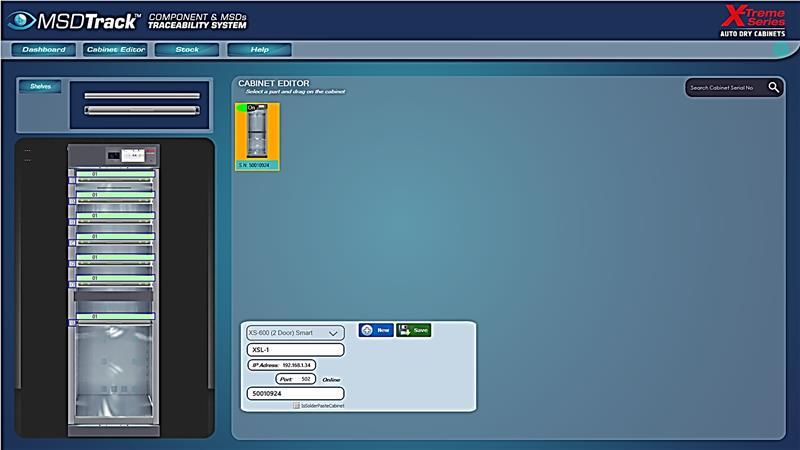

MSDTrackTM – Smart Inventory Tracking Software

Real-Time Monitoring for Moisture-Sensitive Devices (MSDs)

MSDTrackTM is a cutting-edge software solution designed to enhance the management of moisture-sensitive devices (MSDs) in dry storage cabinets. With real-time tracking of floor-life time and physical location, this software ensures that your MSDs are stored and managed according to the IPC-J-STD-033D standards.

By dynamically calculating the remaining floor-life time, MSDTrackTM helps to avoid using expired components, reducing errors and ensuring the highest levels of product quality and reliability.